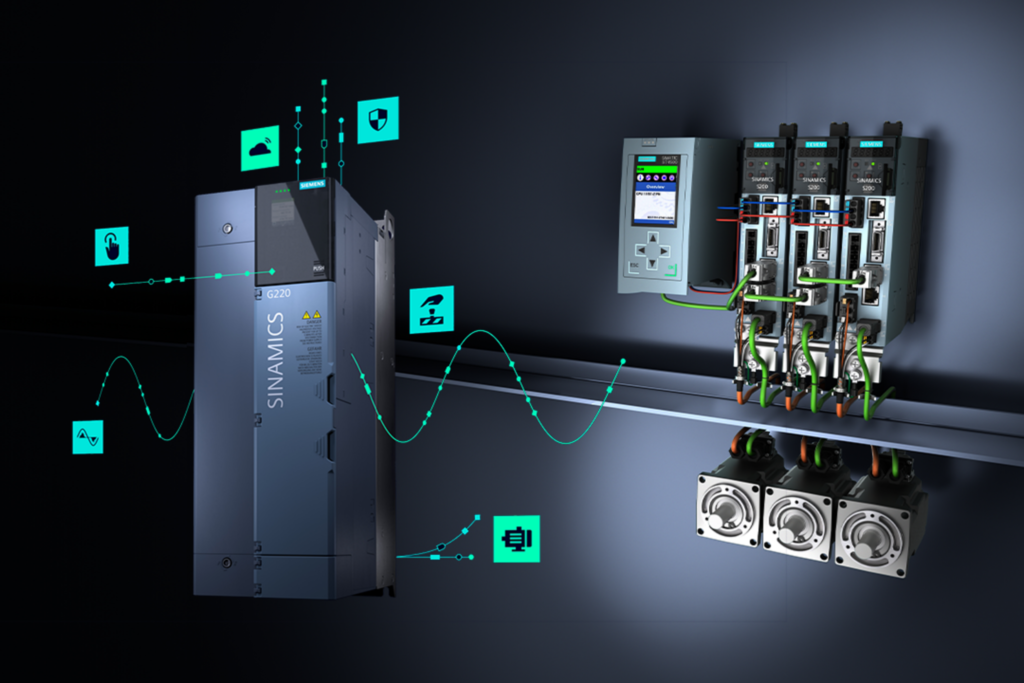

Digitize your low voltage motor

With SIMOTICS CONNECT 400 and SIDRIVE IQ Fleet. Are you interested in getting a quick and comprehensive overview of the operating status of the low voltage motors that drive your applications,

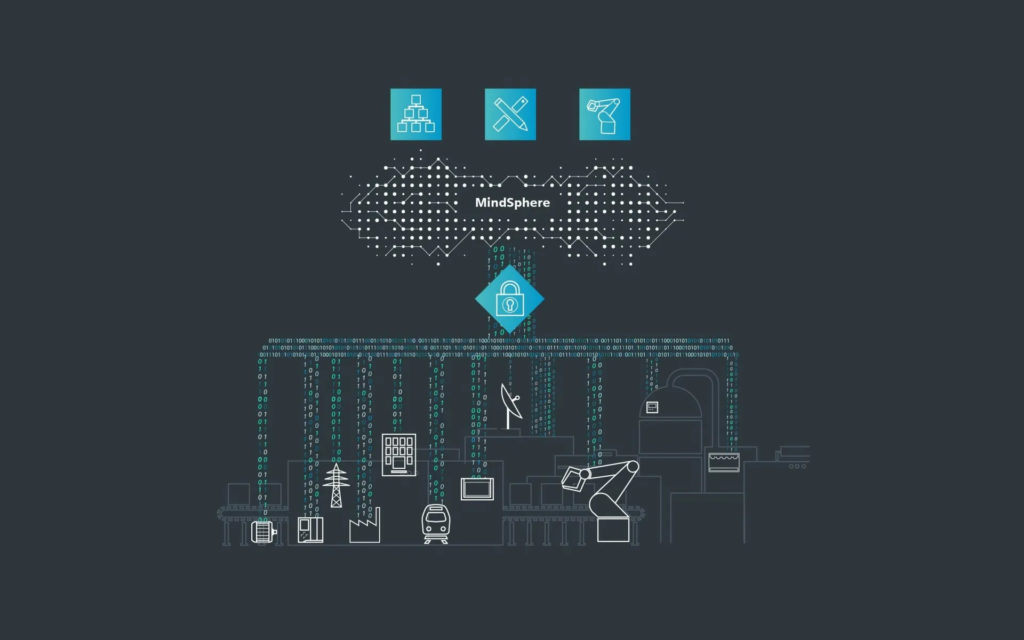

like pumps, fans or compressors? With the SIMOTICS CONNECT 400 plug-&-play connectivity module and the Insights Hub SIDRIVE IQ Fleet analysis application,

You can easily deploy a cost-effective cloud-based solution for continuous, worldwide, 24/7 low-voltage motor health monitoring. Whether monitoring new engines or flexibly upgrading your installed base, SIDRIVE IQ Fleet improves reliability, availability,

efficiency, performance and productivity of low voltage motors